Why is Cooling So Important for Bitcoin Mining?

Bitcoin mining rigs produce an astonishing amount of heat during operation, something I learned firsthand when I first set up my mining farm. Cooling directly impacts miner performance and longevity. Insufficient cooling can cause throttling or damage, leading to profit loss and increased equipment replacement costs.

How Heat Affects Miner Performance

Every ASIC miner is like a high-power electric heater, converting almost all electricity into heat. I remember touching the miner case in summer and feeling a burning temperature. If not cooled promptly, this heat builds up, causing chip temperatures to soar. Overheating chips trigger the miner’s protection mechanism, automatically reducing hash rate or even shutting down. I’ve been woken up by alarms due to miners overheating.

Sustained high temperatures significantly damage hardware. Electronic components age faster under heat, and solder joints can deteriorate due to thermal expansion and contraction. This means ineffective cooling shortens the miner’s functional lifespan, leading to premature replacements and higher long-term costs. After learning the hard way, I started prioritizing the cooling system. Only by keeping miners cool can they run stably and generate consistent profits.

Cooling Methods Determine Operational Efficiency

Cooling affects not just hardware but also mining costs. When temperatures are too high, hash rate drops, and energy efficiency per unit of heat dissipated worsens, essentially “wasting” electricity. Worse, if miners restart intermittently due to heat, each restart means lost mining income. Effective cooling allows 24/7 operation at full speed, directly increasing the farm’s uptime and output.

Running my farm, I also found that the cooling system itself consumes extra power. Numerous fans, exhaust systems, or air conditioners add to the electricity burden. If cooling is inefficient, even more power is needed, which is counterproductive. Therefore, choosing the right cooling method is about finding the optimal balance between performance, power consumption, and cost. In short, cooling is not optional; it’s a core factor affecting a mining farm’s profitability.

Air Cooling vs. Water Cooling for Bitcoin Miners: Pros and Cons

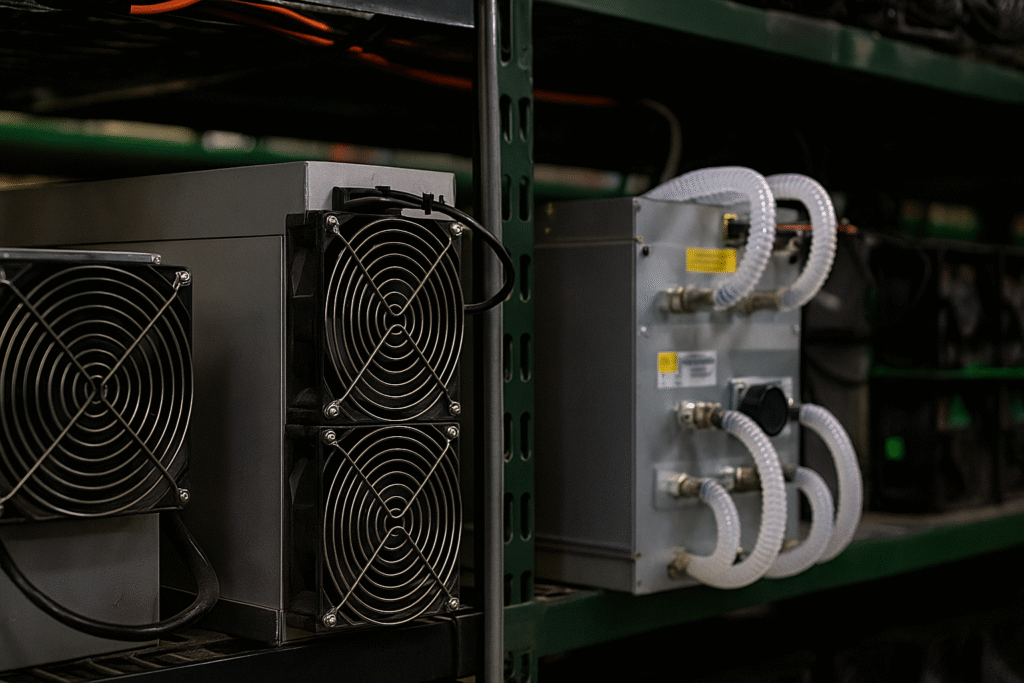

I’ve used both air and water-cooled miners, and each has its endearing and frustrating aspects. Air-cooled miners are simple, low-cost, and easy to deploy but are noisy and affected by ambient temperature. Water-cooled miners are highly efficient and quiet but have complex systems and high initial investment.

Pros and Cons of Air-Cooled Miners

Most traditional miners use air cooling. My first miners also relied on built-in fans. The biggest advantage of air cooling is its simplicity and reliability: multiple high-speed fans inside the miner blow hot air out. Ensuring good farm ventilation so hot air is expelled allows miners to function normally. Air-cooled equipment costs less, and replacing a faulty fan is easy. This straightforward approach was perfect for my startup phase; I could run a few miners just by plugging them in.

However, air cooling has clear disadvantages. First, its efficiency depends on air temperature. During hot, humid summers, the blown air is already hot, making it hard to lower miner temperatures. One summer, I had to install industrial exhaust fans and even air conditioning for support, drastically increasing operational costs. Second, the noise is a problem. Air-cooled miners are very loud under high load, sounding like “airplane engines.” I needed earplugs near my miners, making it nearly impossible for residential or office mining. Another headache is dust: airflow carries dust into the miners, accumulating on chips over time and reducing efficiency, requiring regular cleaning.

In summary, air cooling’s advantages are simplicity, low investment, and easy maintenance; its disadvantages are poor performance in high temperatures, high noise, and requiring good ventilation. For small-scale setups or low-budget scenarios, these aren’t deal-breakers, but when pursuing higher hash rate density or in harsh environments, air cooling starts to fall short.

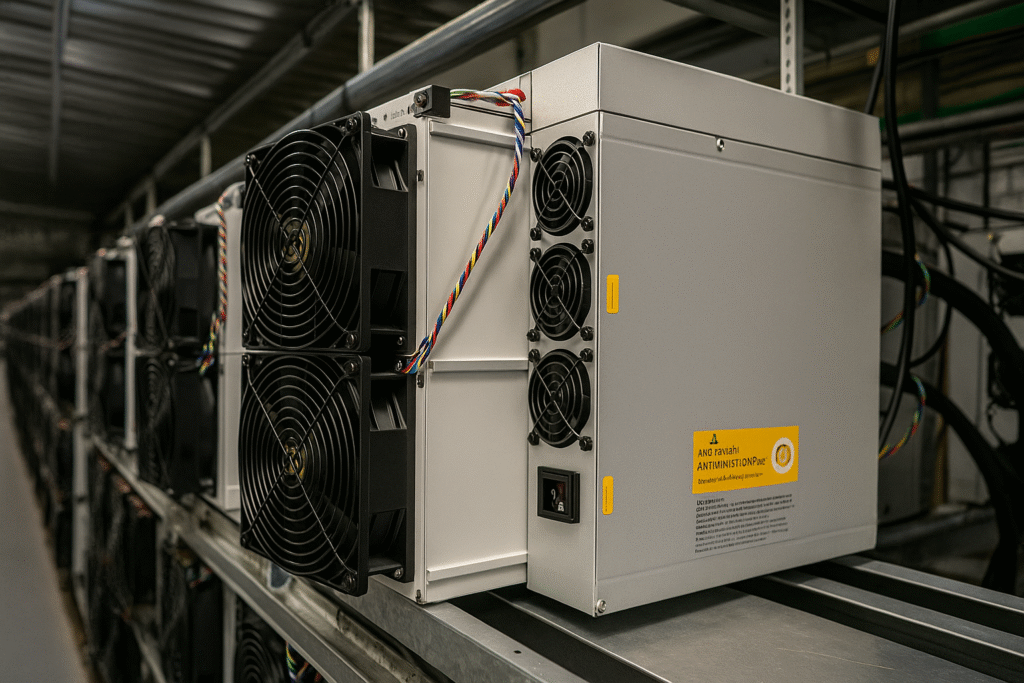

Pros and Cons of Water-Cooled Miners

As mining evolved, I first encountered water cooling (liquid cooling). I was curious how Antminer’s water-cooled versions used liquid to remove heat. Water cooling systems use circulating liquid to absorb heat from the miners, then dissipate it through a radiator. This method offers very high cooling efficiency; water’s thermal conductivity far exceeds air, allowing faster heat transfer from chips. I tested a water-cooled miner, and its chip temperature under full load was much lower than an air-cooled one, running very stably. Later, during summer heat, I relied significantly on water cooling to keep miners running at full speed without throttling.

Another advantage of water cooling is low noise. Water-cooled miners typically lack numerous high-speed fans, replaced by the low hum of a pump. Standing next to a water-cooled miner, it’s noticeably quieter than an air-cooled room. If the farm is near offices or residences, water cooling reduces noise complaints, which is friendly for noise-sensitive locations.

Of course, water-cooled miners aren’t perfect. System complexity and high cost are the biggest barriers. Deploying water cooling requires purchasing components: water blocks, tubing, pumps, radiators, and coolant. This system requires a significant initial investment, and installation and setup need expertise. When I first built my water-cooling system, I encountered leaks; fortunately, I caught them early before damaging machines. This taught me that water cooling maintenance requires more expertise: regularly checking seals, monitoring coolant levels, replacing fluid or additives, etc. In contrast, air cooling maintenance is just cleaning dust and replacing fans, much simpler.

Water-cooled miners also have a hidden energy cost. Although overall efficiency is higher, the pump and any chillers also consume power. However, based on my observation, in large farms, water cooling often uses less electricity than air cooling because it doesn’t require extra fans and air conditioning. Overall, water cooling’s advantages are high-efficiency, quiet operation, stable temperatures, and potential for longer miner lifespan; its disadvantages are high initial cost, complex deployment and maintenance, and a steeper learning curve.

Air Cooling vs. Water Cooling Summary

For a clearer comparison of the two cooling methods, I made this table:

| Comparison Dimension | Air-Cooled Miner | Water-Cooled Miner |

|---|---|---|

| Cooling Efficiency | Relies on air convection; efficiency affected by ambient temperature | Liquid directly absorbs and removes heat; high efficiency and stable temperatures |

| Initial Equipment Cost | Miners include fans; no extra cooling equipment needed; low investment | Miners need water cooling components (blocks, pump, etc.); high initial investment |

| Maintenance Difficulty | Regular dusting, replacing faulty fans; suitable for general technicians | Regular checks of tubing and coolant; requires professional maintenance; risk of leaks |

| Noise Level | Multiple high-speed fans are very loud; unsuitable for populated areas | Essentially no fan noise; runs quietly; can deploy in noise-sensitive environments |

| Deployment Requirements | Needs well-ventilated space to prevent hot air buildup | Requires water source/coolant loop; space must support piping; more complex installation |

| Suitable Scale | Suitable from single units to large farms; the current mainstream solution | Mostly used for large, professional farms; cost hard to justify for small scale |

This comparison shows neither cooling method is perfect; the key is choosing based on your needs and conditions. Many points come from my personal experience, especially the differences in noise and maintenance.

Will Air-Cooled Bitcoin Miners Become Obsolete?

Seeing more new miners adopt water cooling, I wondered if traditional air-cooled miners would become obsolete. Air-cooled miners won’t disappear soon. Most mining farms still use air cooling as the mainstream due to its maturity and low cost. However, as water cooling gains traction in high-end farms, air cooling’s share may gradually decline.

Air Cooling is Still the Current Mainstream

Despite growing interest in water cooling, air-cooled miners still dominate the industry. From my observation, most operating miners are air-cooled, estimated at over 80%. The reason is simple: air cooling technology is mature. From early Antminer S5, S9 series to later S19 series, most miners relied on air cooling. Farms are accustomed to air cooling operations, including site design, ventilation solutions, and maintenance procedures. I’ve visited large farms in Inner Mongolia and Xinjiang with rows of roaring air-cooled miners, running systematically. This long-proven cooling method feels reliable.

Furthermore, air cooling’s low-cost advantage remains hard to beat. For budget-conscious miners or those seeking value, why use water if fans suffice? Deploying water cooling requires infrastructure changes, while air cooling just needs power, internet, and some exhaust fans. Especially during low Bitcoin prices, miners tighten budgets, preferring existing air-cooled equipment over investing in new technology. These practical factors prevent air-cooled miners from disappearing overnight.

The Impact of Water Cooling’s Rise

That said, I clearly feel water cooling technology is gradually emerging and capturing certain segments. New high-end miner models often offer water-cooled versions. For example, Bitmain’s Antminer S19 XP Hyd, S21 Hydro, and MicroBT’s Whatsminer M56S water-cooled version have attracted industry attention. These water-cooled miners often have advantages in power efficiency and hash rate, attracting large farm users pursuing peak performance and lowest energy consumption. Some of my farm owner friends planning new facilities directly designed for water cooling to fit more miners per unit space, increasing hash density. These practices show water cooling is becoming a future direction for large-scale mining.

Does water cooling’s rise mean air cooling will be completely phased out like old technology? Not in the short term. I believe air and water cooling will coexist for a long time, occupying suitable markets. Air-cooled miners will continue serving small/medium miners, retail markets, and regions with ultra-low electricity costs. Water-cooled miners will appear more in well-funded, long-term efficiency-focused large projects. Perhaps years later, when most farms complete upgrades, air cooling might gradually exit the main stage. But around 2025, air-cooled equipment still holds its place and won’t vanish immediately.

Who is Air-Cooled Bitcoin Mining Suitable For?

Choosing air or water cooling largely depends on the miner’s situation. I often ponder: who is better off sticking with air cooling? Air-cooled mining suits small-scale miners, beginners, and those on a tight budget. They seek simple deployment, low investment, and the ability to start mining with existing conditions without complex infrastructure.

The First Choice for Beginners and Small Miners

If you’re new to Bitcoin mining or a small miner with few rigs, air cooling is almost the default choice. That was my path too. The reason is simple: air cooling systems are simple and straightforward, with no high technical barrier. I remember buying my first Antminer, plugging in power and ethernet, the fans spun up, and it started hashing. The process required no other components, easier than assembling a PC. For new miners without an engineering background, avoiding tubes and coolant reduces the psychological barrier to trying mining.

Small-scale miners usually have limited equipment; heat from a few air-cooled miners can be managed with natural ventilation. A friend runs three air-cooled miners in his garage, just installing an exhaust fan in the window to blow hot air out, mining stably for months. For home or small office mining like this, air cooling suffices. Such users are often sensitive to initial cost; air-cooled miners are cheaper and avoid water cooling accessory costs, fitting their budget.

For Budget-Conscious and Cost-Efficiency Focused Individuals

Air cooling also suits miners very concerned about Return on Investment (ROI) and with limited budgets. These individuals meticulously calculate every investment, hoping for quick payback. For them, lower initial investment for air-cooled miners means shorter payback periods and lower risk. Even if air cooling is slightly less efficient than water cooling, the saved thousands can buy one or two extra miners, increasing total hash rate. For example, I once advised a client with enough funds for 10 air-cooled or 8 water-cooled miners. Considering his local electricity wasn’t too expensive, he chose air cooling because the extra hash rate from two more miners outweighed the electricity savings from water cooling.

Furthermore, in locations unsuitable for water cooling, miners have no choice but air cooling. This includes sites without stable water, inability to install piping, or rented spaces forbidding water cooling system modifications. A peer mining in a remote, arid, dusty area relies on air cooling with enhanced dust filters. From cost and practical conditions, air cooling is a pragmatic choice for many miners.

For Those Valuing Flexibility and Easy Maintenance

I find miners who like tinkering and frequently upgrading equipment prefer air cooling for its flexibility and easy maintenance. Miners can be shut down, unplugged, and moved; swapping is very easy. Once a water cooling system is built, modifications aren’t as simple—draining coolant, disassembling pipes is troublesome. So those frequently trading miners, like buying/selling based on market conditions, suit air cooling. Also, if the farm lacks dedicated technicians, with only the miner owner doing daily checks, air cooling is simpler; problems can be solved DIY. This is why many small/medium farm owners choose air cooling: hassle-free.

I’ve compiled typical user types and reasons suitable for air-cooled mining:

| Suitable User Group | Reasons |

|---|---|

| Mining Beginners/Newbies | Low deployment barrier, easy to start, no professional skills needed |

| Small-Scale Farm Owners | Few devices; natural ventilation suffices; no extra investment needed |

| Budget-Limited Miners | Low initial investment, shorter payback period, lower investment risk |

| Frequent Upgraders | System is flexible and easy to modify; adding/removing miners is convenient |

| No Professional Maintenance Team | Maintenance is simple; manageable by individuals; no extra personnel needed |

In summary, anyone pursuing simplicity, low cost, flexibility, and accepting air cooling’s noise and need for good ventilation is well-suited for air-cooled Bitcoin mining.

Recommended models of air-cooled Bitcoin mining machines

Who is Water-Cooled Bitcoin Mining Suitable For?

Compared to air cooling, water-cooled mining suits a different type of miner. I consider which miners are more willing to pay for water cooling’s advantages. Water-cooled mining suits large professional farm operators, well-capitalized miners with technical teams. It’s for projects pursuing high hash density, quiet operation, and long-term mining plans.

Large Farms and Professional Investors

The first group that comes to mind is large farm operators. If you manage a farm with hundreds or thousands of miners, water cooling is often worth considering. I visited a water-cooled farm filled with piping and large heat exchangers, impressive. At this scale, water cooling’s advantages are maximized: higher cooling efficiency allows packing more miners into limited space without overheating, increasing hash rate output per unit area. A client in the Middle East chose water cooling for this reason—high local temperatures and cheap electricity; they wanted to maximize miners in limited space, and water cooling solved the thermal bottleneck.

Professional mining investors and large companies also prefer water cooling. These players are usually well-funded, focusing more on long-term returns and stability than immediate device cost. They calculate full lifecycle ROI, finding that although water cooling has high initial cost, miners running cooler last longer, and extended lifespan’s extra mining income can offset the investment. Also, large farms often have their own engineering teams capable of maintaining water cooling systems, less worried about technical challenges. So teams with technical and financial strength are willing to use water cooling for high-spec farms.

Those with Specific Environmental or Regulatory Needs

Some choose water cooling due to special environmental or policy considerations. For farms in cities or populated areas, noise and heat emission issues must be solved, otherwise complaints or shutdowns can occur. Here, water cooling’s quiet operation and controllable heat dissipation shine. I saw a case in Shenzhen deploying water-cooled miners in an office building—heat was guided outdoors via exchangers, indoors felt little heat and no deafening noise. This allows farms to operate stealthily in urban buildings, not disturbing residents and being safer.

Also, miners focusing on green energy and environmental metrics lean towards water cooling. Higher efficiency means less electricity consumed per Bitcoin mined, lower carbon footprint. Water cooling systems are typically closed-loop, saving water and not emitting extra waste heat, easier to pass environmental reviews. I heard of Nordic farms using water cooling to recycle miner heat for building heating, killing two birds with one stone. These innovative models appeal to miners with environmental goals or seeking policy support.

Those Pursuing Peak Performance and Long-Term Returns

The last group is geek-type miners or long-termists. They’re interested in maximizing miner performance; water cooling allows lower temperature operation, enabling stable overclocking or higher hash rate output. A mining geek friend modded old miners with immersion cooling for overclocking, enjoying it thoroughly. This represents a pursuit of ultimate efficiency. Water cooling, as an officially supported efficient method, is safer and more robust than DIY mods for these miners.

Meanwhile, miners committed to long-term operation are more willing to invest in water cooling. They aren’t planning quick payback in 1-2 years but aim to mine for 5, 10 years. For them, heavy upfront investment in a water-cooled farm is a long-term capital expenditure, years of lower operating costs and longer hardware lifespan. If Bitcoin mining remains profitable, water cooling’s benefits might show after year 3 or 4. Personally, I’m considering introducing water cooling if my farm scales up significantly with long-term power guarantees to reduce overall costs.

The table below summarizes user groups and reasons suitable for water-cooled mining:

| Suitable User Group | Reasons |

|---|---|

| Large Farm Operators | Large-scale deployment needs efficient cooling; water cooling increases hash density & stability |

| Well-Capitalized Miners/Companies | Focus on long-term returns; can handle high initial cost; pursue extended hardware life |

| Operators in Noise/Heat Restricted Areas | Water cooling is quiet with directed heat dissipation; suitable for urban/office areas with restrictions |

| Energy Efficiency & Eco-Conscious Miners | High energy efficiency reduces electricity per hash rate; meets environmental standards; allows waste heat reuse |

| Teams with Strong Technical Capability | Possess engineering maintenance skills; can manage complex systems; leverage water cooling for performance |

In summary, miners with strong capital, technical resources, specific environmental requirements, or pursuing long-term benefits are better suited for water cooling. For them, water cooling’s advantages translate more fully into actual returns.

Recommended models of water-cooled Bitcoin mining machines

Detailed Cost Analysis: Air Cooling vs. Water Cooling for Bitcoin Mining

Beyond performance and suitability, we must calculate the economics. I’ve specifically compared cost differences between air and water cooling. Overall, air-cooled mining has lower initial and maintenance costs, while water-cooled mining offers slightly better power efficiency but requires higher equipment and operational investment, needing long-term cost amortization.

Initial Purchase Cost Comparison

When purchasing miners, water-cooled versions of the same model are often significantly more expensive. Taking Bitmain’s Antminer S21 series as an example: the air-cooled S21+ (235T) costs ~$3525, while the corresponding water-cooled S21+ Hydro (358T) costs ~$5370, almost double. This means miners choosing water cooling pay much more upfront. I found when purchasing that per TH/s price for water-cooled models is 30%-50% higher than air-cooled. For budget-limited miners, this is a significant barrier. Note: water-cooled versions usually have higher hash rates, but cost per TH/s is still higher.

Besides the miner itself, water cooling requires additional cooling equipment, another substantial expense. Each water-cooled miner needs water blocks, tubing, pumps, coolant, and heat exchangers (e.g., radiators or cooling towers). This setup costs hundreds to over a thousand dollars per kW of cooling power. I roughly calculated that configuring water cooling for 20 miners might cost equivalent to several extra miners. Air-cooled miners need almost nothing extra; a high-power fan and rack cost little. Thus, air cooling has a clear advantage in initial investment; saved funds can be used for electricity or liquidity, precious for small miners.

Electricity & Efficiency Cost Comparison

Electricity is one of the biggest daily operational costs. Cooling methods affect miner power consumption and add ancillary power costs. Miner-wise, water-cooled models are usually slightly more energy-efficient. Using S21+ as an example: air-cooled 235T consumes ~3564W, ~15.2W/TH; water-cooled 358T consumes ~5360W, ~15.0W/TH. The efficiency gap is roughly 10%, meaning water-cooled versions don’t scale power consumption linearly with higher hash rate, slightly lower per TH.

But the miner is only part of the system. Air cooling system electricity costs mainly come from fans and possible air conditioning. Built-in miner fans aren’t small; large ASIC miner fans might use 200-300W each. If the farm environment is hot, you might need extra exhaust fans, industrial blowers, or chillers, all adding up. My personal experience: adding one 5HP AC in summer skyrocketed monthly electricity bills, significantly reducing profits.

In contrast, water cooling system electricity costs are mainly for the pump and circulation devices. Typically, a water cooling pump set consumes a few hundred watts, serving multiple miners simultaneously. Large farms might have cooling towers or industrial heat exchange systems, also consuming power. But because water has higher heat capacity, moving the same heat often requires less power than air circulation. Also, water-cooled miners concentrate most heat for outdoor dissipation, reducing need for indoor AC, saving more electricity. So overall, for large-scale deployment, electricity cost per unit hash rate for cooling is lower for water cooling; for small scale, the difference is minimal, or water cooling might be slightly higher due to idle losses.

To make this concrete, here’s a daily electricity cost example (assuming electricity cost ¥0.5/kWh, approx. $0.07/kWh):

| Metric | Air-Cooled S21+ 235T | Water-Cooled S21+ Hydro 358T |

|---|---|---|

| Miner Power Consumption (Watts) | 3564 W | 5360 W |

| Daily Electricity Consumption (kWh) | ~85.5 kWh | ~128.6 kWh |

| Miner Built-in Cooling Power Use | Fans ~300W | Pump ~200W |

| Additional Cooling Equipment Power | May need AC/Exhaust Fans (extra kW) | Needs Cooling Tower/Fans (several kW for large farms) |

| Daily Electricity Cost (@¥0.5/kWh) | ~¥42.8 | ~¥64.3 |

| Electricity Cost per TH/s Daily | ~¥0.182 | ~¥0.180 |

(Note: Data is estimated; additional cooling power considered for large farms, may be zero for small scale)

The table shows water cooling is slightly more efficient miner-wise, but considering the entire system, water cooling’s electricity cost per TH/s is lower for large farms, while for small farms the difference is minimal or air cooling might be cheaper. This confirms the earlier point: larger scale maximizes water cooling’s efficiency advantage; smaller scale finds air cooling sufficient.

Maintenance & Operational Cost Comparison

Daily farm operations include labor, consumables, and part replacements. Air and water cooling differ here too.

Air cooling maintenance costs are relatively simple, mostly regular dust cleaning. I schedule powering down miners every 1-2 months, using compressed air to blow dust off heatsinks and fans, ensuring airflow. This is labor-intensive but not highly costly, doable by workers or oneself. Also, air-cooled miners’ main wear parts are fans. Luckily fans are cheap; I keep spares, replacing a faulty fan in minutes. For me, this is “minor work,” costing little annually.

Water cooling maintenance costs are more complex. First, coolant needs regular replacement or topping up. If using antifreeze, it might need changing every 6-12 months to prevent reduced performance or pipe corrosion. I need to source suitable coolant, a recurring cost. Second, the pump has a lifespan, requiring monitoring and replacement. Most importantly, checking for leaks. Even if pressure-tested during installation, joints can degrade and seep over time. I almost daily inspect tubing, fearing leaks. Once I found a puddle, shut down and searched half a day to find a slightly cracked joint leaking coolant; luckily caught early before damage. Handling such incidents is much more troublesome than replacing fans, usually needing specialized technicians.

For labor costs, small air-cooled farms might not need dedicated personnel; one person can manage dozens of machines. But water cooling systems are best served by technicians familiar with the technology, both for emergencies and regular checks. This increases labor costs compared to air cooling. When calculating long-term farm costs, I budget extra for annual water cooling maintenance, while air cooling mostly ignores this.

Comprehensive Cost-Benefit Consideration

Summarizing the above: air cooling saves money and hassle; water cooling costs more and requires more effort but runs efficiently. Air cooling suits those wanting low-investment operation and quick payback, as upfront costs are low and maintenance simple, even if electricity costs are slightly higher, it’s a controllable operational expense. Water cooling suits farms with long-term plans, willing to invest more capital early, recouping costs later through electricity savings and longer hardware life. It’s like choosing between a traditional gasoline car and a hybrid—gasoline is cheaper but less efficient; hybrid is expensive but efficient; worthiness depends on usage scenario and duration.

When making decisions, I listed a cost comparison checklist, roughly as discussed, then calculated which method offered the best total cost/benefit ratio based on farm scale, electricity cost, and investment horizon. This analysis is necessary; every miner should carefully calculate before choosing the cooling solution most aligned with their own interests.

How to Choose Between Air and Water Cooling for Bitcoin Mining?

With so many differences understood, the final step is deciding which cooling method to use. I often base my decision on several key factors. Choosing between air and water cooling depends on farm scale, budget, electricity costs, and environment. Miners should assess their situation: small-scale/low-cost favors air cooling; large-scale/high-demand favors water cooling, considering long-term profit goals.

Consider Farm Scale and Number of Devices

The first factor is farm scale and number of devices. Small-scale farms usually suit air cooling, as heat from a few to dozens of miners can be managed with simple air cooling. When I started with just over ten machines, I never considered water cooling—overkill. If you have few miners, simply adding exhaust fans or improving ventilation can meet cooling needs, no need for complex water cooling. However, when scaling to hundreds or thousands of devices, air cooling’s limitations appear: air’s heat dissipation capacity is limited; large clusters keep room temperatures high. Either reduce per-unit power (losing hash rate) or introduce stronger cooling, i.e., water cooling. Generally, under a few dozen units use air cooling; over a few hundred consider water cooling; the middle ground requires weighing other factors.

Consider Budget and Return on Investment (ROI) Period

Budget size directly influences cooling choice. If funds are tight, pursuing quick payback, air cooling fits better. Lower air cooling initial investment means less debt pressure and lower risk; maybe electricity costs and output break even in half a year to a year. I calculated air cooling payback around one year. Choosing water cooling equipment could double the budget and extend payback to over two years, too long and uncertain for a small beginner miner. Therefore, when budget is limited or capital cost is high, air cooling is safer.

Conversely, with ample funds willing for long-term investment, accepting 2-3+ year payback periods, water cooling’s later efficiency advantages can materialize. Also consider electricity costs: in high-cost environments, water cooling’s electricity savings significantly help profits, speeding payback; with very low electricity, efficiency advantages become less relevant, and payback depends more on equipment cost. This is why some water-cooled farms locate in areas with expensive electricity but climate unsuitable for air cooling—high electricity costs need water cooling’s efficiency for better returns. If electricity is very cheap (e.g., ~¥0.2/kWh hydropower), people tend to buy more cheap air-cooled miners for quantity over fewer expensive water-cooled ones saving electricity. In summary, when calculating economics, include equipment amortization, electricity costs, and miner lifespan, then choose based on acceptable payback period.

Consider Operational Environment and Constraints

The farm’s local environmental conditions and restrictions significantly impact cooling choice. Climate is paramount: if your farm is in cold regions like Northeast China or Canada, where temperatures are low most of the year, air cooling can even use natural cold air for “free AC,” prioritizing air cooling under such favorable conditions. In hot, humid places like the Middle East or Southeast Asia, air cooling underperforms, AC costs are high, and water cooling better handles heat, quickly expelling it to maintain normal operation. So choosing based on climate is key, “adapting to local conditions.”

Site conditions are also crucial. If the farm is in a remote, spacious warehouse where you can freely install vents and fans, air cooling faces no obstacles. But if in urban buildings or locations with strict fire safety codes, water cooling, being a closed loop with controllable heat exchange, might easier pass approvals. Also, noise regulations, waste heat emission standards, etc.; if local rules exist, air cooling might struggle to comply, forcing water or even immersion cooling. I participated in a farm site evaluation project where a city data center wanted to use excess power for mining but required no noise or hot air disturbing residents; the final solution directly chose immersion cooling (similar principle to water cooling). Thus, environmental conditions and regulations can directly determine the technical path, sometimes overriding miner preferences.

Consider Own Technical and Operational Capability

Choosing a solution must match one’s abilities. As mentioned, air cooling maintenance is simple, manageable by one person; water cooling involves specialized skills. If the mine owner or team lacks members familiar with water cooling systems, hastily adopting water cooling carries higher risks. If problems arise mid-way with no one to fix them, losses could be significant. So if you lack technical background or can’t hire relevant talent locally, air cooling is a more realistic choice. Conversely, if you’re hands-on, love technical challenges, or have HVAC engineers, you can boldly try water cooling, trading skill for efficiency.

A compromise strategy is gradual progression: start with a batch of air-cooled miners, simultaneously learning water cooling knowledge, piloting small-scale water cooling equipment, and gradually expanding the water cooling ratio after gaining experience. This is the current state of many farms—air cooling dominant, with some hash rate for water cooling experiments. This prepares both ways, avoiding total loss from betting wrong.

Selection Recommendations for Different Scenarios

Summarizing the above factors, here are some typical scenarios and suitable cooling choices for reference:

| Miner/Farm Situation | Recommended Cooling Solution |

|---|---|

| Small farm with <50 devices, tight budget | Air Cooling (Low investment, easy management) |

| Located in cool climate with good ventilation | Air Cooling (Leverage natural cooling) |

| Large farm with 100+ devices | Water Cooling (Improve cooling efficiency, reduce density limits) |

| Located in high-temperature or poor ventilation environment | Water Cooling (Maintain stable performance in heat) |

| Expensive electricity, high electricity cost proportion | Water Cooling (Save energy, reduce long-term electricity costs) |

| Cheap electricity, minimal electricity cost concerns | Air Cooling (Save on equipment, more miners are better) |

| Farm in residential or office building | Water Cooling (Quiet operation, controllable heat emission) |

| No professional maintenance, only personal oversight | Air Cooling (Simple system, easy problem handling) |

| Has technical team support, pursues cutting-edge tech | Water Cooling (Leverage team capability, gain technical dividends) |

The table isn’t absolute but reflects general selection directions. Each miner must decide based on unique circumstances. The best approach is consulting experienced individuals (including supplier opinions), weighing pros and cons, then making the decision most aligned with your own interests and goals.

Air Cooling vs. Water Cooling Bitcoin Mining ROI Comparison

Theoretical discussion must return to actual profits. Finally, I want to use an intuitive case study to compare air and water cooling Return on Investment (ROI). Under identical mining conditions, due to higher initial cost for water-cooled models, despite better hash rate and efficiency, air-cooled models typically have faster payback; water-cooled models require longer to recoup investment.

Case Background

For a fair ROI comparison, I selected two current market-representative miner models as samples:

- Air-Cooled Miner: Antminer S21+ (235T), air-cooled, 235 TH/s, ~3564W power, ~$3525 unit price (incl. PSU).

- Water-Cooled Miner: Antminer S21+ Hydro (358T), water-cooled, 358 TH/s, ~5360W power, ~$5370 unit price (incl.cooling, as a complete unit).

Assume both miners operate in the same farm environment, electricity cost unified at ¥0.5/kWh (~$0.07/kWh), Bitcoin price and network difficulty at current levels. Expected daily Bitcoin output value differs, but we focus on net profit and payback period.

Daily Revenue and Expense Comparison

Based on hash rate and power consumption, we can estimate daily mining revenue and electricity costs:

- Air-Cooled S21+ 235T daily mining revenue ~$10.5, consumes ~85.5 kWh, electricity cost ~$6.0, thus daily net profit ~$4.5.

- Water-Cooled S21+ 358T daily mining revenue ~$16.0, consumes ~128.6 kWh, electricity cost ~$9.0, thus daily net profit ~$7.0.

The water-cooled miner, with higher hash rate, earns more Bitcoin daily, hence higher net profit. But remember, its purchase cost is much higher; higher net profit doesn’t automatically mean better value; we must check ROI further.

Payback Period Calculation

ROI (payback period) refers to the time needed to recoup the initial investment. Rough calculation based on daily net profit:

- Air-Cooled S21+ initial $3525/ $4.5 daily ≈ 783 days to break even.

- Water-Cooled S21+ initial $5370/ $7.0 daily ≈ 767 days to break even.

We see, under current assumptions, the air-cooled miner breaks even in about 2 years 1 months, while the water-cooled miner needs about 2 years 1 month too.

Of course, this is a static calculation; actual ROI is affected by Bitcoin price, mining difficulty, electricity cost changes, etc., dynamically changing daily. For example, if next year the coin price doubles with unchanged electricity costs, both miners’ daily profits surge, and the water-cooled miner, with a higher profit base, might see its payback period shorten more; conversely, if the coin price halves, both might become unprofitable, extending ROI indefinitely. However, under identical environmental trends, the relative gap between air and water cooling usually persists because the initial cost multiple remains.

Long-Term Returns and Other Considerations

Simple investment payback years is just one metric; we must also consider miner wear, depreciation, and long-term profit potential. Water-cooled models have some long-term potential advantages not reflected in short-term ROI: e.g., lower operating temperatures may reduce failure rates, and actual operational lifespan might exceed air-cooled miners by 1-2 years. If air-cooled miners become unreliable in year 3 due to heat-induced aging, while water-cooled miners batch operate until year 5, the latter’s continuous income in later years acts as an “extension,” potentially yielding more total profit.

Also, resale value matters. Large farm equipment purchasers value miner resale value in the secondary market. Some buyers prefer water-cooled miners (maybe due to existing local water cooling facilities), leading to relatively higher used prices. If sold after some operation, water-cooled miners recover more residual value, compensating part of the upfront cost. Air-cooled miners have high market liquidity, but used prices are competitive due to high supply. This is also worth mentioning in ROI analysis.

However, these long-term benefits are somewhat uncertain, while upfront costs are real. So most miners still tend to focus on 2-3 year ROI when making investment decisions. Currently, the air cooling solution is more favorable in terms of ROI, especially for small/medium miners where fast capital turnover is more important; water cooling is for large players pursuing long-term returns, requiring more patience and risk tolerance.

Conclusion

Whether you choose air cooling or water cooling, weigh the pros and cons against your resources and goals to find the solution that best fits your mining farm’s needs. Contact Miner Source Team Purchase Now!